Add:

Dongguan Fortuna Metals CO., Ltd

No. 226, Shida Road, Dalingshan Town, Dongguan 523810, Guangdong, China

"What is lead frame? is that one question which if ever arises in your mind, you would be confused about in any case. And if you did, then take a humble heart as you are definitely not the only one. Well, lead frames are incredibly important; however, the understanding of the same can prove to be tricky.

Let me try and explain what lead frames are in simple words, including reasons for their existence and uses found by them in the semiconductor industry.

So, relax and let us proceed with our discussion on lead frames.

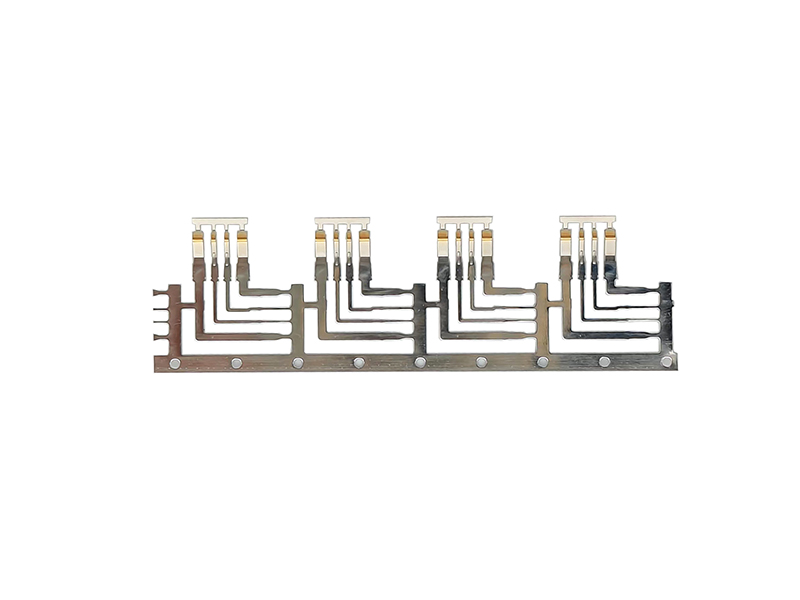

In short, a lead frame can be described as a skeleton forming the package of semiconductor chips. It refers to an actually mechanical support part for a semiconductor chip that provides an electrical connection with some other external circuitry. Most of the time, lead frames are made using metals such as copper, copper alloys, and iron-nickel alloys.

Commonly, the lead frame includes a die pad that accepts the chip, provided with leads formed of metal wire for interconnection between the chip and the external circuitry. In many cases, the leads are bent to some configurations for enhanced contact with the circuit board.

One thing for sure is that lead frames have helped a great deal in the packaging of semiconductors. It offers a kind of support system on which the silicon chip is placed, thus holding them together and facilitating constant electrical connection between the chip and the package.

For instance, it helps in heat dissipation originating from the chip during its operational performance, a factor that greatly maintains the performance and lifespan of the product. On an overall basis, lead frames play a crucial role in enabling compact, reliable, and high-performance production in the semiconductor industry.

But how does it work, this lead frame? It will be explained below.

The lead frame works by providing a stable platform for mounting and connecting the semiconductor chip. It consists of a die pad, where the chip is attached, and lead wires that connect the chip to the external circuitry.

1. Die Attachment: The semiconductor chip is attached to the die pad using a conductive adhesive or solder. This attachment is crucial as it provides a path for electrical signals to flow between the chip and the lead frame.

2. Wire bonding: After this procedure, the wire bonding process must follow. Using thin wires, a bond is made from the contact pads on the chip to the leads of the lead frame. This way, an electrical connection is established from the chip to the outside world/external circuitry.

3. Encapsulation: Encapsulation involves packaging the assembly into a protective material, which is used to protect the chip and wire bonds from any damages brought about. It also possesses certain levels of heat sinking of power obtained from the chip.

4. Lead Forming: The leads of the lead frame are normally formed into a particular shape for connection with the circuit board. Formation processes, in this regard, include the contouring of the leads at optimal alignment points toward the contact pads of the circuit board.

5. Testing: The testing is possible only after the assembly of the lead frame. Checking for the very basic functionality of the semiconductor chip as well as the integrity of the wire bond are stringently quality-controlled and carried out only after the completion of the assembly of the lead frame. This becomes very vital for verifying the reliability and performance of the ultimate electronic product.

It is through this way that the lead frame operates by offering a stable and reliable platform over which the semiconductor chip is able to mount and connect to, thereby making it possible for one to manufacture compact and high-performance electronic devices.

The lead frames have revolutionized machining in several ways:

Miniaturization now calls for modern lead frames, characterized by a level of precision machining techniques to be high so that the structures of die pads, lead wires, and leads can be formed very accurately and aligned. This has precipitated the development of CNC machining technology to meet stringent requirements in production.

Lead frames have allowed miniaturization of electronic devices by providing a compact and efficient way of attaching and interconnecting semiconductor chips. For that reason, development has to be done so as to produce smaller and highly precise components for lead frames.

While all these lead-frame advantages are important, they have meant a huge opportunity for the electronics manufacturer to reduce the cost of electronic devices. And it supports high-volume, high-speed manufacturing at relatively low material and process costs because it is included with all its benefits.

The above-created drive toward specific types of machining methods and processes would maximize the efficiency of lead frame production.

This led to greater efficiencies in the production process, as improvements in machining led by lead frame production enabled faster production times while minimizing waste and improving quality control.

Overall, lead frames have impacted machining and further technological means applied in the electronics fields, as a great contribution to driving cost-effective and efficient practices.

There are diverse industries and machines that make use of lead frames. However, having argued as above, some predominant areas of use can be noted within the scope of electronics and semiconductor industries.

Some areas of utility are:

1. Semiconductor Packaging: The chief use is semiconductor packaging wherein the lead frames assist in giving a stable platform for mounting semiconductor chips and connecting the same. They happen to form an important part of integrated circuits (ICs) and other electronic appliances.

2. Automotive electronics: Lead frames, prepared to the required form, are used in different automotive electronic components like the driving control unit, airbag sensors, and anti-lock braking systems. The main application for these frames is in providing both electrical connections and mechanical support for the semiconductor chips within the system.

3. Consumer Electronics: The lead frames are, without a doubt, used in countless consumer electronics, whether it is the smartphone, tablet, or laptop. It enables the packaging of microprocessors, memory chips, and various other semiconductor devices.

4. Led Lighting: Lead frames find their applications in LED lighting to hook or bond together with the contacts of PCB-mounted LED chips. They ensure an electrical connection from the different chips for heat removal needed by the LED to function ideally.

5. Medical Devices: These include a number of implantable medical devices in their type, such as sensors, pacemakers, and defibrillators. Their function helps in necessary connection for semiconductor chips to operate reliably under some of the most arduous environments presented in medicine.

6. Telecommunications: Basic equipment in telecommunications that makes use of lead frames includes signal processing to data transmission, all geared to keeping a continued network of connection and reliability on these systems.

7. Industrial Equipment: There are several forms of industrial equipment and machinery that use the lead frames for monitoring and control services. Some of the important functions are to provide necessary connections for the use of semiconductor chips in industrial automation systems, along with sensors for the application purpose.

From the above discussion, it can be said that lead frames do play a very important role in distinguishing the performance and functionality features in several machines and respective industries, thus making an indispensable element of current electronics and semiconductor manufacture.

Copyright © 2023 Dongguan Fortuna Metals Co, Ltd. | All Rights Reserved.